Logistics and supply chain management rely heavily on established safety protocols and operational best practices, with secure and efficient palletisation being pivotal to safe operations. Correct processes ensure the safe transport of goods, optimise storage space and significantly reduce costs.

To help understand the intricacies involved in palletising products correctly, we’ll cover the best practices for palletisation and explain why getting it right matters so much.

The Basics of Palletisation

Palletisation involves arranging products on a pallet in a way that maximises stability and safety. Here are the key steps to follow:

1. Choose the Right Pallet

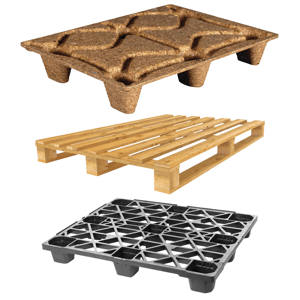

- Material. Pallets come in various materials like wood, plastic, and metal. Choose one that suits your products' weight and nature.

- Size. Ensure the pallet size matches your storage and transport requirements.

2. Arrange Products Strategically

- Uniformity. Place products of similar size and weight together to ensure even distribution.

- Layering. Stack products in interlocking layers to enhance stability. Use a brick or pyramid pattern to avoid weak points.

3. Secure the Load

- Strapping. Use straps to hold the load together.

- Stretch Wrapping. Wrap the entire pallet with stretch wrap to prevent movement and protect from dust and moisture.

- Corner Protectors. These add extra stability and prevent product damage from straps or handling.

4. Mind the Weight Distribution

- Bottom-Heavy. Place heavier items on the bottom and lighter ones on top.

- Center of Gravity. Keep the load’s centre of gravity low and centred to avoid tipping.

5. Follow Safety Regulations

- Compliance. Adhere to industry regulations and standards like the ISO guidelines for palletising. This ensures safety and compatibility with different transport systems.

Why Correct Palletisation Matters

Correct palletisation is more than just a best practice; it’s a necessity for several reasons:

1. Prevents Product Damage

Proper palletisation minimises the risk of products shifting, falling, or being crushed during transit. This is essential for maintaining product integrity and customer satisfaction.

2. Optimises Space

Efficient palletisation maximises the use of available space in warehouses and during transport. This can lead to significant cost savings and improved operational efficiency.

3. Improves Safety

Poorly palletised loads can be hazardous to workers. Proper palletisation ensures that loads are stable and secure, reducing the risk of accidents and injuries for warehouse workers and logistical partners in transit and during loading and offloading processes.

4. Reduces Costs

Minimising product damage and optimising space reduces the overall costs associated with transportation and storage. This can improve your bottom line and make your logistics operations more competitive.

5. Improves Efficiency

Well-palletised products are easier to handle with forklifts and other machinery. This streamlines loading and unloading processes, saving time and labour costs.

Common Mistakes to Avoid

To ensure you’re palletising correctly, be mindful of these common mistakes:

- Overhanging Products - Products extending beyond the pallet edges can be easily damaged and destabilise the entire load.

- Ignoring Weight Limits - Overloading a pallet can cause it to break, leading to product damage and safety hazards.

- Poor Wrapping - Inadequate shrink wrapping can result in products shifting or falling off the pallet.

Closing Thoughts on Correct Palletisation

Correct palletisation is a cornerstone of effective logistics and supply chain management. By following best practices, you can protect your products, optimise space, enhance safety, and reduce costs. At Allpack, we’re committed to helping you achieve these goals with our range of high-quality packaging and palletising solutions.

For more information on how we can assist you with your palletisation and safety-boosting needs, please contact us today by sending us a message, emailing sales@allpack.uk.com or call 01543 396 700. We’re on hand to help you ensure your products reach their destination safely and efficiently.