The automotive industry demands more from packaging than most. There are numerous factors to consider, including the storage and transportation of high-precision components, and the cost implications of shipping high-value parts within global supply chains. With this in mind, packaging needs to do more than just protect. It must be resilient, efficient, sustainable and smart.

We’ve worked closely with manufacturers, OEMs and suppliers across the sector, giving us a front-row view of the evolving demands. From ever-shifting production volumes to stricter compliance and growing pressure to hit sustainability targets, the challenges are varied. It stands to reason the right packaging can make a measurable difference.

Built for the Journey: Strong, Sustainable Protection

Automotive components range from delicate electronics to heavy panels, often moving across long distances and climates. The choice of packaging must be able to resist impact, vibration, moisture and temperature shifts while keeping parts secure.

Today’s newest solutions are making that easier and more sustainable. Multi-layer corrugated packaging is now strong enough to rival wood and plastic crates, but it’s lighter, recyclable and easier to handle. High-performance foams, paper-based inserts and edge protectors help reduce the need for excess material.

Take honeycomb packaging, for example. Designed for parts like engine components and trim, it provides a recyclable alternative to polystyrene while improving protection and reducing waste during transit.

Reducing Waste While Cutting Costs

As outlined, sustainability is now front and centre across the automotive industry. Companies are replacing traditional plastic-heavy packaging with recyclable materials that can be reused or returned within the supply chain. The shift often delivers more than environmental benefits, as it can also lead to smarter use of space, easier disposal and long-term savings.

In a key example of this, BMW has invested in returnable packaging systems to cut back on single-use materials and boost logistics efficiency in recent years. These reusable units were integrated to lower waste and lessen the total cost of ownership across the supply chain, making the move a win-win for the automotive giant.

Boosting Efficiency with Smarter Design

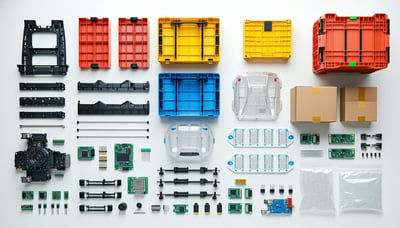

Speed and accuracy are essential on the shop floor. The right packaging speeds these up, improving handling, simplifying identification and supporting lean manufacturing. That’s where custom packaging comes in, tailored to fit parts precisely, stack efficiently and slot seamlessly into production lines.

Examples include colour-coded inserts for easier sorting, modular crates for mixed loads and RFID-enabled packaging that can be tracked across facilities. Ford is also using recycled plastic to make protective components and packaging items, such as underbody shields, helping to reduce their environmental footprint and material spend.

Reusable packaging is also gaining ground, especially for tier-one suppliers managing frequent shipments. Tough corrugate or recycled plastic options can handle multiple returns and still be recycled at the end of life.

Packaging with Purpose

No two parts are the same, and neither are the challenges they face in transit. That’s why tailored packaging makes a difference. Whether your goal is to meet ESG targets, lower damage rates, or save space in your supply chain, packaging can play a critical role in helping with these aspects.

We can assist with making tangible improvements to your packaging process, and providing sustainable alternatives to the consumables you use. We are here to help you with your next packaging project and move towards a more sustainable future.

Want to see how sustainable packaging can improve your operations? Call us on 01543 396 700, email sales@allpack.uk.com or send us a message. We’d love to help you build a greener, smarter packaging system that works for your business.