The key to efficient packaging logistics extends far beyond just moving parcels from A to B. It’s a prime opportunity to make a significant environmental difference. Increasingly, businesses are focusing on their green credentials and ESG objectives, so optimising packaging logistics should be a sizeable component of this offering, providing a smart, measurable path to improvement.

From selecting innovative materials to maximising lorry loads, here are the most effective ways to reduce carbon emissions through more efficient packaging logistics.

1. Rethink Your Materials

The materials you choose are a fundamental starting point. A significant win for reducing emissions is switching to lighter, more compact options. It stands to reason that lighter materials mean less fuel burned during transport and less valuable space taken up in your warehouse.

Corrugated cardboard, for instance, continues to be a popular choice. It's not just recyclable; its strength-to-weight ratio is excellent. Using more recycled content is another effective strategy, as it reduces the 'embodied carbon' (the CO2 emissions associated with producing the packaging itself), particularly when materials are sourced and manufactured locally. The less distance your packaging travels to reach you, the better for its carbon footprint.

2. Reduce Air, Not Just Waste

It’s a common sight: oversized boxes for small items. Over-packaging is a key offender in inefficient logistics. Every centimetre of unused box space means you are, in effect, shipping air. This consumes fuel, increases vehicle loads, and ultimately raises carbon emissions. 'Right-sizing' your packaging is the solution. This involves using just enough material to protect the product effectively, without leaving significant empty voids. Using fit-for-purpose designs or flexible packaging that adapts to the product’s shape, such as corrugated wrap or paper cushioning, can substantially reduce the volume per unit shipped.

3. Maximise Every Pallet and Lorry Load

Transportation often accounts for the largest portion of carbon emissions in the supply chain. If pallet and lorry space isn’t fully utilised, the emissions per unit shipped invariably increase. The objective is to be highly efficient with space, like a well-played game of Tetris with your packages. This involves designing packaging that stacks neatly and efficiently, resisting compression, and maintains consistent dimensions across different SKUs. Smart interlocking boxes that result in stable stacking formats not only prevent product damage but also allow for more strategic load planning. It’s also worth exploring bulk shipping strategies. Consolidating shipments into fewer, fuller loads reduces the total number of deliveries and the fuel consumed across the supply chain.

4. Focus on Reverse Logistics and Returns

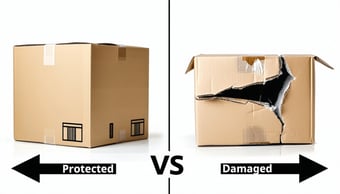

Returns are unwelcome for many reasons, and they're also an often overlooked source of additional emissions. When a damaged item is returned, repacked, and re-shipped, its carbon footprint can more than double.

Those investing in reliable, protective packaging and perhaps testing it against real-world distribution conditions can avoid these repeat journeys and the extra carbon they generate. Similarly, designing packaging for reuse or easy return can streamline reverse logistics processes and cut emissions in return handling.

5. Source Closer, Smarter

The origin of your packaging materials is significant. Sourcing them from suppliers closer to your fulfilment centres or warehouses reduces inbound logistics emissions. This approach also allows for more agile inventory management, reducing the risk of over-ordering or emergency restocks that necessitate high-carbon air freight. When possible, working with local or regional suppliers who meet sustainability standards adds another layer of environmental value, and often cuts lead times as well.

6. Align Teams Across the Supply Chain

Achieving greener packaging logistics isn't solely the responsibility of one department. It requires close collaboration across functions, from product design and packaging engineers to inventory planners and shipping partners. When all departments are aligned on shared sustainability goals, businesses can make smarter packaging decisions from the outset. For example, small adjustments to product shape or weight early in the design process can lead to significant improvements in transport efficiency later on.

7. The Fundamentals of Better Packaging in Logistics

As we've explored, packaging logistics offers a lot of opportunities to reduce carbon emissions, often enhancing operational efficiency at the same time. Focus on smarter materials, optimising loads and coordinated systems to significantly lessen your environmental impact. This approach is a clear advantage for both the environment and your bottom line.

We've supported many businesses across diverse sectors in their transition to more efficient and sustainable packaging systems. If you're keen to enhance your eco-packaging processes, we're here to assist. Please send us a message, give us a call on 01543 396 700, or send us an email at sales@allpack.uk.com.