When it comes to sustainable packaging solutions, businesses are constantly looking for ways to improve efficiency, reduce waste, and streamline their operations. With material choices, workflow efficiency and even safety to consider, making note of areas for improvement can quickly become overwhelming.

In this blog, we will simplify matters and explore the benefits of customising your pack station layout to improve workflows, cut waste, and reduce downtime, and why it's more than just a passing fad.

Improved Workflow Efficiency

A bespoke packing bench allows you to optimise the layout of your pack station according to your specific requirements. Every business is unique, with different products, packaging materials, and workflow needs. By customising your pack station layout, you can create a more efficient workflow that minimises unnecessary movements and maximises productivity, leading to better savings in the long term.

For example, switching to portable, modular void-fill dispensers offers a range of usability benefits for warehouse staff. From lightweight, boxed paper dispensers and on-stand options to high-speed automated machines, integrating several transportable options into your pack stations allows staff to access void fill materials with speed and ease.

By doing away with fixed void fill hoppers, packing operatives save time on travelling to centralised dispensers to fill cartons and parcels. Paper alternatives and air pillows also allow for more measurable, repeatable material use over time.

In addition, a well-designed packing bench can also improve ergonomics and safety. By considering factors such as height-adjustable work surfaces, proper lighting, and comfortable seating, you can create a workspace that promotes employee well-being and reduces the risk of injuries. This, in turn, contributes to a more productive and efficient workforce.

Waste Reduction

Customising your pack station layout also enables you to implement waste reduction strategies. With a bespoke packing bench, you can incorporate features that promote sustainable practices and minimise waste generation.

Increasing the number of waste disposal bins in your warehouse or fulfilment centre reduces pack times overall (since time spent locating and removing excess material is cut) and facilitates a simpler, streamlined clean-up during busy periods. Creating dedicated waste points for different materials also serves to improve your recycling and waste management processes too, since materials can be processed with added speed and ease.

By reducing waste, not only are you boosting your operation’s sustainability profile, but you are also cutting costs associated with excessive packaging materials. This can lead to significant savings in the long run, contributing to your overall business profitability.

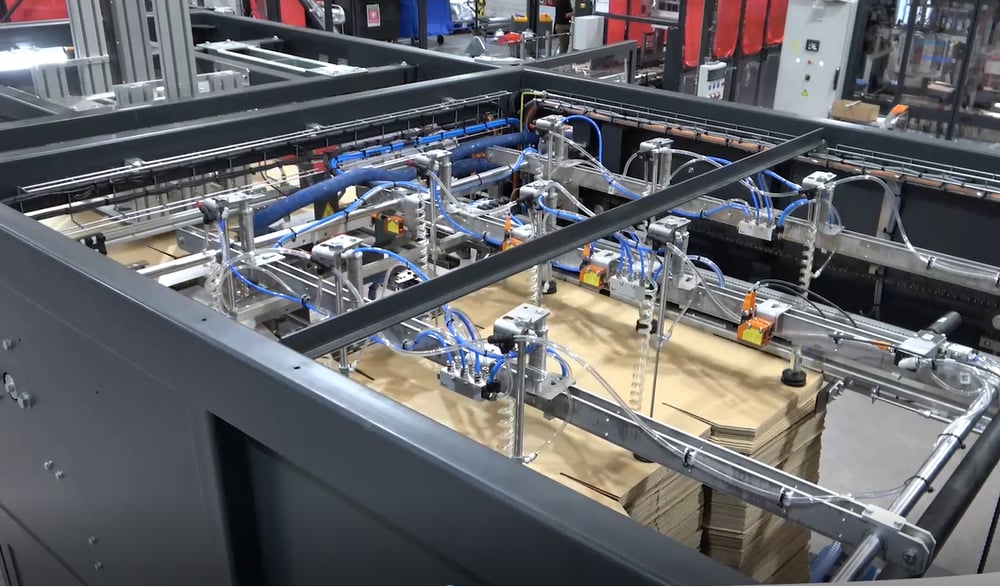

Upgrade to automated systems

If your business is experiencing ongoing growth and a subsequent uptick in throughput, leading to more handling for warehouse staff, it may be time to consider automated packing machines to add expediency and efficiency to your operation.

From carton erectors, box sealers and in-line labellers, to auto-folding machines and lidding units, packaging automation is the ideal choice for businesses wishing to scale for growth, letting you redirect your workforce to focus on other core duties such as order processing and loading items for transportation.

The Path to Increased Efficiency

Ultimately, bespoke pack benches are far from being just a passing fad. Customising your pack station layout offers numerous tangible benefits that can lead to increased efficiency, waste reduction, and reduced downtime. By optimising workflows, promoting sustainable practices, and addressing inefficiencies, businesses can significantly improve their packing operations.

We understand the importance of tailored solutions. Our expert team can work closely with you to design and implement a customised pack station layout that suits your specific requirements. Whether it's optimising workflow efficiency, reducing waste, or cutting downtime, we are committed to helping businesses achieve their sustainability goals while improving operational effectiveness.

If you're ready to take the next step toward a more efficient and sustainable packing operation, get in touch with us today. Together, we can create a bespoke packing bench that sets your business on the path to increased efficiency and success.

Discover actionable insights for enhancing supply chain transparency and increasing environmental viability with our Sustainability Brochure. Packed with tips and guides, it provides practical ways to reduce emissions and cut avoidable waste for good.

If you're interested in learning more about our bespoke solutions and consultations in packing process efficiency, we encourage you to reach out to us today. We are available by phone at 01543 396700, by email at sales@allpack.uk.com, or you can visit our website at www.allpack.uk.com to learn more about our sustainability-driven services and products.