Wrapping it Up: The Fundamentals of Stretch Wrap and Exploring Different Film Types

When it comes to shipping and logistics, pallet wrapping might seem like a mundane task, but its importance cannot be overstated. Properly securing goods on pallets ensures safe transportation and delivery, minimising the risk of damage and loss. One of the key elements in this process is selecting the right type of pallet wrap, considering factors such as durability, efficiency, and application method. In this blog post, we'll outline the fundamentals of wrapping pallets and explore the different types of pallet wrap available in the market.

Understanding Pallet Wrap Types: Cast vs. Blow, Hand vs. Machine

Pallet wrap comes in various types, but two primary distinctions are cast and blown film. These terms refer to the manufacturing process and result in different properties and performance characteristics.

Cast Film vs. Blown Film

Cast Film

Cast film is produced through a process where melted resin is extruded through a flat die onto a chill roll, resulting in a thin, consistent film. This type of film typically offers excellent clarity, high tensile strength, and good puncture resistance. It's suitable for a wide range of applications and is often preferred for its cost-effectiveness and versatility.

Blown Film

Blown film, on the other hand, is manufactured by blowing melted resin vertically upwards through a circular die. This process creates a thicker film with irregular properties, including higher stretchability and cling. Blown film is known for its resilience and ability to conform to irregular loads, making it ideal for heavy or unstable pallets.

Hand Wrap vs. Machine Wrap

Hand Wrap

Hand wrap is manually applied by workers using handheld dispensers. It offers flexibility and control, allowing for precise wrapping tailored to each pallet's size and shape. Hand wrap is suitable for smaller operations or situations where portability and versatility are crucial.

Hand wrap can be efficiently applied using hand dispensers like the Grip Film Twist Lock Magnetised Applicator, providing ease of use, safer wrapping and improved efficiency.

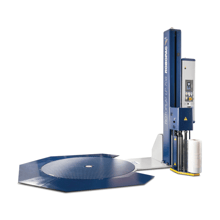

Machine Wrap

Machine wrap is designed for use with pallet wrapping machines, offering automation and efficiency for high-volume operations. Machine wrap provides consistent tension and coverage, reducing the risk of human error and ensuring uniform wrapping. It's ideal for large warehouses or distribution centres where speed and productivity are paramount.

We offer a range of efficiency-boosting machinery for machine film, and our team can assist in the delivery and installation of these units, ensuring seamless integration into your operations and more versatile operations to help you scale.

Core Benefits and Applications of Each Film Type

Hand Cast Film

- Benefits: Hand cast film combines the clarity and strength of cast film with the flexibility of manual application. It offers excellent puncture resistance and load stability while allowing for easy handling and tear-off.

- Applications: Hand cast film is suitable for a wide range of pallet wrapping tasks, from securing lightweight goods to stabilising heavy loads. It's commonly used in retail, manufacturing, and logistics industries.

Hand Blown Film

- Benefits: Hand blown film excels in tough environments where puncture resistance and load retention are critical. Its high-stretch capabilities ensure a tight wrap, even around irregularly shaped loads.

- Applications: Hand blown film is ideal for securing heavy or bulky items that require extra protection during transit. It's commonly used in construction, automotive, and industrial settings.

Machine Cast Film

- Benefits: Machine cast film offers the same quality and performance as hand cast film but with the added efficiency of automated wrapping. It delivers consistent results and maximises throughput in high-volume operations.

- Applications: Machine cast film is well-suited for large-scale distribution centres, warehouses, and manufacturing facilities with continuous pallet wrapping needs.

Machine Blown Film

- Benefits: Machine blown film combines the durability of blown film with the speed and precision of machine wrapping. It ensures secure containment and stability for heavy loads while minimising material usage.

- Applications: Machine blown film is preferred for wrapping pallets with irregular shapes or sharp edges, providing reliable protection during transportation and storage.

The Last Word on Pallet Wrapping

Choosing the right type of pallet wrap is essential for ensuring the safe and secure transportation of goods. Whether opting for cast or blown film, and whether selecting hand or machine application, each type offers distinct advantages suited to different operational requirements. In understanding the core benefits and applications of each film type, businesses can make informed decisions to optimise their pallet wrapping processes and safeguard their valuable cargo.

Our extensive range of stretch film options caters to various needs, whether you prioritise strength, sustainability, or cost-effectiveness. To explore further details on how we can assist you in elevating your packaging sustainability and diminishing your environmental impact, we encourage you to reach out to us today. You can easily get in touch by sending us a message, phone 01543 396 700 or emailing us at sales@allpack.uk.com. We’re on hand to guide you on your path towards a more sustainable future.